Are you looking for a comprehensive overview of platinum thermocouples? Look no further! This guide aims to provide detailed insights into platinum thermocouples, from fundamental principles to advanced applications. As an expert with extensive experience in the field, I’ve witnessed firsthand the critical role platinum thermocouples play in temperature measurement and control across various industries. Join me as we explore the world of platinum thermocouples and uncover their significance in industrial processes.

Understanding the Basics of Platinum Thermocouples

What is a Platinum Thermocouple?

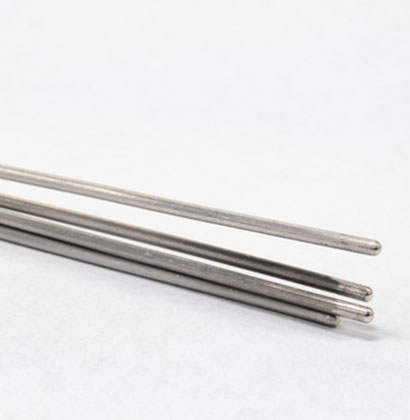

A platinum thermocouple is a vital temperature sensor that utilizes platinum as one of the conductors to measure temperature variations. It operates on the principle of the Seebeck effect, where a voltage is generated across the junction of dissimilar metals in response to a temperature gradient. The exceptional accuracy, stability, and reliability of platinum thermocouples make them indispensable in critical industrial processes.

How Does a Platinum Thermocouple Work?

Platinum thermocouples rely on the unique temperature-dependent electrical properties of platinum to accurately measure temperature. When exposed to different temperatures, the voltage produced at the junction of the platinum wires changes in a predictable manner. This voltage change is then correlated to the temperature being measured, allowing for precise temperature monitoring and control in diverse applications.

Types of Platinum Thermocouples

There are various types of thermocouple platinum, categorized based on the ratio of platinum to rhodium in the conductors. Common types include the Type R (platinum/rhodium – 13% / platinum), Type S (platinum/rhodium – 10% / platinum), and Type B (platinum/rhodium – 30% / platinum-rhodium – 6%). Each type has specific temperature ranges and characteristics, catering to different industrial requirements.

| Types of Platinum Thermocouples | Composition | Temperature Range |

| Type R | Pt / Rh 13% | -50 to 1768°C |

| Type S | Pt / Rh 10% | -50 to 1768°C |

| Type B | Pt / Rh 30% / Pt-Rh 6% | 0 to 1820°C |

The Advantages of Using Platinum Thermocouples

Exceptional Accuracy and Stability

One of the primary advantages of thermocouple wire platinum is their unparalleled accuracy and stability, especially at high temperatures. Their predictable and consistent output ensures precise temperature measurements even in harsh operating conditions, making them indispensable in critical processes where temperature control is paramount.

High-Temperature Capability

Platinum thermocouples excel in high-temperature applications, outperforming many other thermocouple types. With the ability to withstand extreme temperatures without compromising accuracy, they are widely utilized in processes such as heat treatment, aerospace applications, and industrial furnaces.

Longevity and Reliability

Platinum thermocouples have a reputation for longevity and reliability, providing consistent performance over extended periods. Their robust construction and resistance to oxidation and corrosion contribute to their extended operational lifespan, reducing maintenance requirements and operational downtime.

How to Choose the Right Platinum Thermocouple for Your Needs

Consider the Temperature Range

When selecting a platinum thermocouple, it’s crucial to assess the temperature range of the intended application. Different types of platinum thermocouples have distinct temperature capabilities, and choosing the appropriate type ensures accurate and reliable temperature measurements.

Evaluate Environmental Conditions

Assessing the environmental conditions, such as potential chemical exposure, abrasion, or vibration, is essential in determining the most suitable platinum thermocouple for a specific application. Certain industrial environments may require additional protection or specialized sheathing to ensure the thermocouple’s longevity and performance.

Compatibility with Control Systems

Compatibility with existing temperature control systems and instrumentation is a critical consideration. Ensuring seamless integration with control systems facilitates accurate temperature monitoring and control, optimizing overall operational efficiency.

Tips for Installing and Maintaining Platinum Thermocouples

Proper Installation Techniques

Correct installation is paramount for the optimal performance of platinum thermocouples. Employing proper techniques, such as ensuring adequate insulation, secure connections, and precise positioning, is crucial to maintain accuracy and reliability.

Regular Calibration and Testing

Regular calibration and testing are essential to verify the accuracy of platinum thermocouples. Periodic checks and adjustments guarantee consistent and precise temperature measurements, minimizing the risk of process deviations and ensuring product quality and safety.

Preventive Maintenance Practices

Implementing preventive maintenance practices, such as routine inspections and cleaning, safeguards platinum thermocouples against potential issues that could compromise their performance. Proactive maintenance enhances longevity and reliability, minimizing the likelihood of unplanned downtime.

Exploring Advanced Applications of Platinum Thermocouples

Aerospace and Defense

Platinum thermocouples play a pivotal role in aerospace and defense applications, where precise temperature measurement is critical for engine monitoring, exhaust gas analysis, and materials testing in extreme conditions.

Semiconductor Manufacturing

In semiconductor manufacturing, platinum thermocouples are utilized for temperature profiling in processes such as wafer fabrication and thermal treatment, ensuring consistent and controlled heating and cooling cycles for optimal semiconductor production.

Industrial Furnaces and Incinerators

The high-temperature capabilities of platinum thermocouples make them indispensable in industrial furnaces and incinerators, where accurate temperature monitoring is vital for efficient and controlled combustion processes.

In conclusion, platinum thermocouples are integral instruments for accurate temperature measurement and control across a diverse range of industries. Their exceptional accuracy, stability, and high-temperature capabilities make them indispensable in critical applications where precise temperature monitoring is paramount. By understanding the basics, advantages, selection criteria, installation, maintenance, and advanced applications of platinum thermocouples, industries can harness their full potential to ensure operational efficiency and product quality.