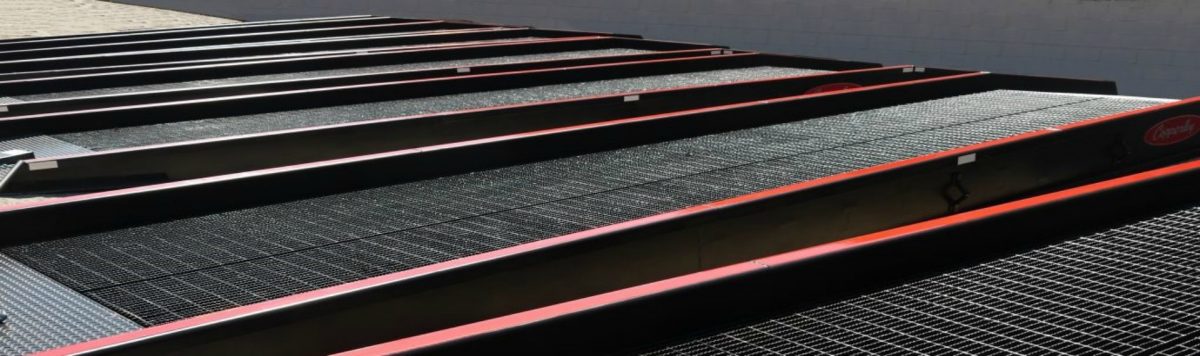

Steel Yard Ramps

As the leader in custom steel fabrication for over 50 years, Copperloy is the leader in steel yard ramps. Proudly manufactured in the USA, Copperloy’s steel yard ramps are designed for strength and durability.

Big Steel Yard Ramps for Heavy Loads

Copperloy’s big steel yard ramps are some of the strongest in the industry. Made from A572-50 high-strength steel with a 50,000-pound minimum yield, these ramps can handle the biggest loads. Indeed, their capacities range from 16,000 to 60,000 pounds with widths of either 70 or 84 inches. Furthermore, our ramp’s hydraulic hand pump allows you to quickly make height adjustments of 38 to 65 inches.

Why Copperloy Uses A572-50 High-Strength Steel on Their Steel Yard Ramps

As the industry leader in manufacturing and selling loading dock equipment, Copperloy insists on using the best material possible. A572-50 HSLA steel plates have a flat, clean surface, are stronger than mild steel, and provide incredibly high yield strength in a surprisingly light package. In permanent or moveable yard ramps where superior strength is required, a relatively light end product weight is a major plus.

Having reliable steel yard ramps can solve a variety of loading applications. Copperloy’s patented box frame has many key features. First, safety is a leading priority. Ramps feature safety curbs, a securely resting platform lip, and high-strength steel deck grating. Next, mobility is essential. Position your steel yard ramps the way you want them with the positioning sleeve. Additionally, tow yard ramps short distances using the add-on towbar feature.

Steel Yard Ramp Safety

OSHA Guidelines for Forklift Use on Steel Ramps

OSHA’s guidelines for forklift ramp safety are related to speed and maintaining a slow, controlled ascent or descent on the ramp. Specific requirements include:

- 29 CFR 1926.451(e)(5)(ii)– “No ramp or walkway shall be inclined more than a slope of one vertical to three horizontal (20 degrees above the horizontal).”

- 29 CFR 1910.178(n)(7)– “Grades shall be ascended or descended slowly.”

- 29 CFR 1910.178(m)(6)– “A safe distance shall be maintained from the edge of ramps…”

The design of the forklift ramps from Copperloy helps meet these requirements, keeping forklift operators safe.

The number of forklift fatalities by industry and type of accident:

|

Fatal Accident Type |

% |

|

Where fatalities occur |

% |

|

Crushed by vehicle tipping over |

42% |

|

Mining |

1.2 |

|

Crushed between vehicle and a surface |

25% |

|

Construction |

23.8 |

|

Crushed between two vehicles |

11% |

|

Manufacturing |

42.5 |

|

Struck or run over by a forklift |

10% |

|

Transportation |

11.0 |

|

Struck by falling material |

8% |

|

Wholesale trades |

12.5 |

|

Fall from platform on the forks |

4% |

|

Retail trade |

9.0 |

Choosing Dock Ramps That Comply With OSHA Requirements

Whether you need a yard ramp that can provide access to trucks in the shipping yard, or an auxiliary mobile ramp for your loading dock, OSHA compliance begins with picking the right heavy-duty, safest ramp for the job.

In light of the number of accidents on forklifts, OSHA estimates 85 fatal forklift accidents per year; 34,900 forklift accidents result in serious injury; and 61,800 are classified as non-serious. Copperloy takes ramp safety seriously in all the features of their yard ramp safety features. This data is supported by the Industrial Truck Association, which estimates there are about 855,900 forklifts in the U.S. Therefore, over 11% of all forklifts will be involved in some type of accident each year.

Contact Copperloy to learn more about ramp safety and alignment with OSHA guidelines.

Truck Ramp Rentals Safety Tips

While using your truck ramp rental, Copperloy is a resource you can count on. With a goal to provide all the skills and tools for success while using their dock equipment. Find quick tips below!

RAMP SAFETY

Know Equipment Capabilities

Made in the USA, Copperloy steel yard ramps are engineered for industrial use. Though built with high-strength metals, everything has limits. Be sure not to exceed maximum load capacity.

Secure with Wheel Chocks

Standard ramp features mixed with dock equipment accessories are the recipe for loading task success. Copperloy accessories include aluminum wheel chocks which prevent dangerous movement during loading. Snug, maximum holding protects against involuntary movements from jolts and shifting.

Unload on a Level Surface

The ground below the ramp should be solid. Ideally, unload on concrete or pavement.

Secure Ramp Connection

The lip of the ramp should be securely resting on the dock or truck. Additionally, connect safety chains when needed.

Transport at Safe Speeds

Operators should not exceed 5mph when using the towbar. Also, it is not intended for long-distance towing. Additionally, the positioning sleeve is meant to adjust and reposition the ramp, not for towing.

Maintain and Inspect Ramp Conditions

Before use, check for signs of rust or damage. For ramps that use hydraulic height adjustment, check hydraulic fluid levels. Then, check the loading dock. It is also important to regularly inspect for cracks, damage, and more. Visit the Copperloy website to learn more.

Built with Safety in Mind

When it comes to safety, their big steel yard ramp’s seven-inch curb takes the stress of heavy loads and prevents accidental vehicle run-off. In addition, a 15-inch lip ensures the ramp rests firmly in place. For extra security, safety chains are also included. Another standard safety feature is their high-strength serrated steel deck grating. This construction helps to ensure an all-weather, high-traction running surface. And finally, the beveled low-end plate eliminates bumps and jolts for forklifts. See the Copperloy website to learn more.