Deep draw stamping is a crucial process in manufacturing intricate metal components efficiently. Whether you are in the automotive, aerospace, or medical industries, choosing the right deep draw metal stamping supplier is essential for project success. This comprehensive guide will provide you with all the necessary information about deep draw stamping suppliers, from the process itself to the essential qualities to look for in suppliers, along with valuable tips for finding the ideal partner for your specific requirements.

Unveiling Deep Draw Stamping: An In-Depth Overview

What is Deep Draw Stamping?

Deep draw stamping is a metal forming technique that transforms flat sheet metal into three-dimensional shapes. This method involves pulling a metal blank into a die cavity using a punch, creating a seamless, hollow structure. Ideal for producing components with high depth-to-diameter ratios like cups, cans, and enclosures, deep draw stamping offers advantages such as cost-effectiveness, repeatability, and versatility with various metals.

How Deep Draw Stamping Works

The deep draw stamping process begins by placing a flat metal sheet onto a blank holder. A punch then drives the metal into a die cavity, shaping it into the desired form. Through multiple drawing operations, the metal undergoes successive stages, progressively increasing the part’s depth. By precisely managing parameters like material thickness, lubrication, and die geometry, manufacturers can create precise components with tight tolerances.

Applications of Deep Draw Stamping

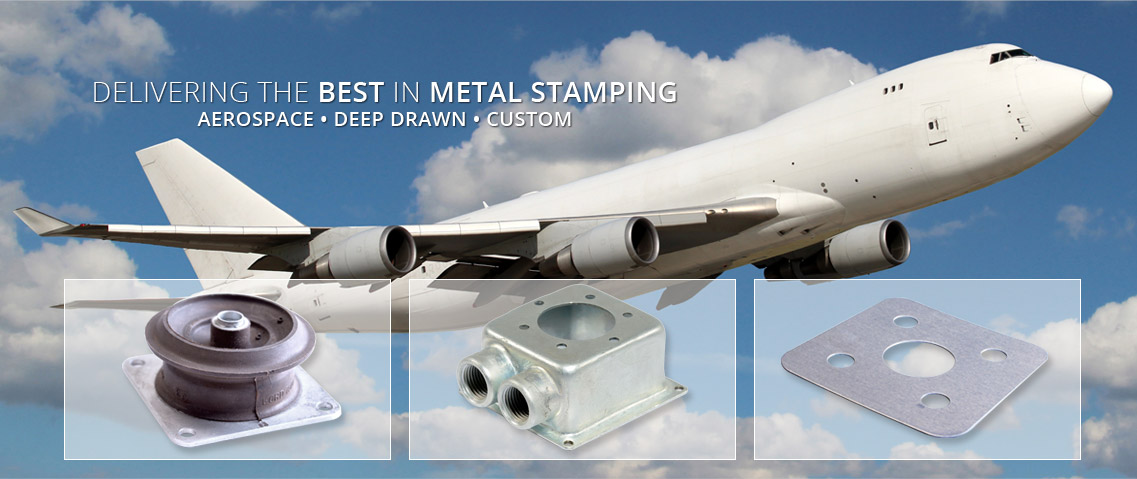

Deep draw stamping finds widespread application across industries for manufacturing components with intricate geometries and high structural integrity. Common uses include automotive parts like exhaust systems and fuel delivery components, household items such as cookware and electronic enclosures, medical devices, aerospace components, and industrial equipment. Its capability to form complex shapes with minimal material waste makes it a preferred manufacturing method.

Key Attributes to Seek in Deep Draw Stamping Suppliers

1. Experience and Expertise

When choosing deep draw stamping suppliers, prioritize those with a proven track record of delivering top-notch components. Opt for companies with extensive industry experience and a deep understanding of the stamping process. Experienced suppliers can troubleshoot issues effectively, optimize designs for manufacturability, and propose cost-effective solutions.

2. Advanced Technology and Equipment

Leading deep draw stamping suppliers invest in cutting-edge technology and equipment to ensure precision and efficiency in their processes. Check if suppliers utilize computer-aided design (CAD) software for tooling and simulation, along with modern presses featuring programmable controls. Advanced equipment enhances product quality, reduces lead times, and cuts overall production costs.

3. Quality Control Measures

Quality control is paramount in deep draw stamping to ensure the consistency and accuracy of produced parts. Choose suppliers with robust quality management systems like ISO certifications and adherence to industry standards. Look for suppliers conducting thorough inspections throughout the manufacturing process, including material testing, dimensional checks, and surface finish evaluations.

Comparing the Best Deep Draw Stamping Suppliers in the Industry

When evaluating deep draw stamping suppliers, consider multiple factors to make an informed decision. Assess aspects like pricing, lead times, quality standards, and communication channels. Request quotes from various suppliers, inquire about capabilities, capacity, and past projects to identify the supplier aligning best with your project requirements and budget.

| Criteria to Consider | Best Deep Draw Stamping Supplier A | Best Deep Draw Stamping Supplier B | Best Deep Draw Stamping Supplier C |

| Pricing | Competitive rates | Transparent pricing structure | Customized quotes available |

| Lead Times | Quick turnaround | Flexible lead time options | On-time delivery guaranteed |

| Quality Standards | ISO certifications | Stringent quality control measures | High-quality materials used |

| Communication Channels | Responsive customer support | Multiple communication channels | Regular project updates provided |

| Capabilities | Wide range of metal options | Specialization in complex shapes | Secondary operations available |

Tips for Selecting the Right Deep Draw Stamping Supplier for Your Project

1. Clearly Define Your Requirements

Before engaging with suppliers, clearly outline your project requirements, including part specifications, quantities, and quality standards. Providing detailed information upfront enables suppliers to evaluate your project’s feasibility accurately and offer tailored solutions. Clearly communicate expectations regarding lead times, pricing, and desired outcomes for a successful partnership.

2. Request Samples and References

When assessing potential suppliers, request samples of their prior work to gauge quality and craftsmanship. Additionally, seek references from past clients to assess satisfaction levels and the supplier’s reliability. Reviewing samples and speaking with references provides valuable insights into the supplier’s capabilities, communication style, and commitment to customer satisfaction.

3. Establish Open Communication Channels

Effective communication is crucial for a successful partnership with a deep draw stamping supplier. Choose a supplier emphasizing transparency, responsiveness, and collaboration throughout the project lifecycle. Discuss expectations regarding project updates, timeline adjustments, and potential challenges upfront to foster a seamless working relationship.